to the climate transition and is a key factor for a sustainable future in industry, energy and mobility.

As experts in the use of hydrogen, we are developing systems together with partners to drive the hydrogen economy forward.

In doing so, we are contributing to a green future and ensuring that this technology becomes safe and widely available.

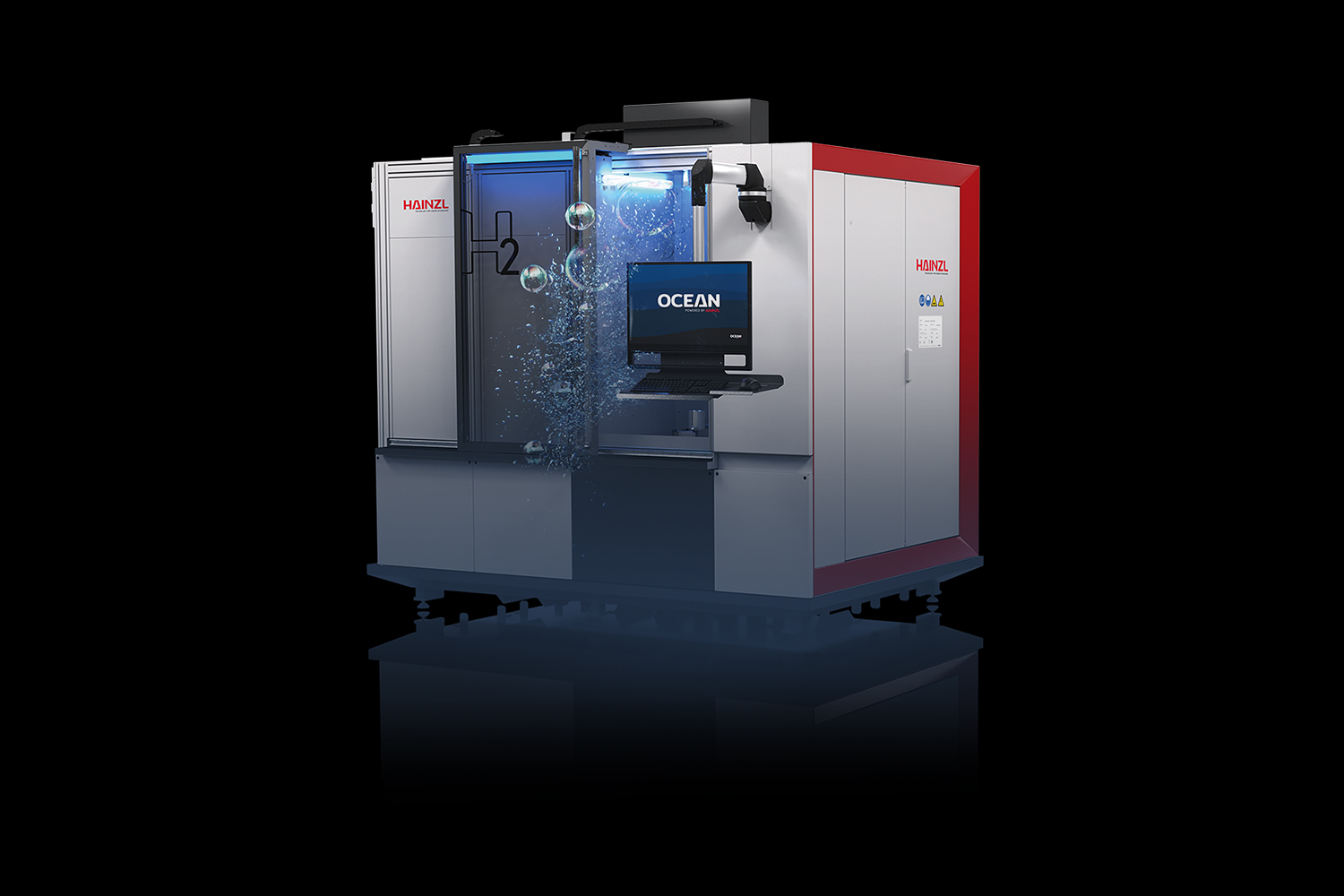

Our testing systems for hydrogen components, system solutions for electrolysis and H2 infrastructure enable our partners to develop safe components and systems for hydrogen applications.

HAINZL PEM electrolyzer - the turnkey solution for the production of green hydrogen.

// Scalable plug-and-play solution from 1.25 MW connected load

// Dynamic operating mode from 10 - 100

// Compact and modular design

// Flexibility for different applications

// Independent automatic operation with remote maintenance

// 24/7 service

Optional features:

// Waste heat extraction

// Oxygen utilization

// AEM suitability

HAINZL PEM electrolyzer - the turnkey solution for the production of green hydrogen.

// Scalable plug-and-play solution from 1.25 MW connected load

// Dynamic operating mode from 10 - 100

// Compact and modular design

// Flexibility for different applications

// Independent automatic operation with remote maintenance

// 24/7 service

Optional features:

// Waste heat extraction

// Oxygen utilization

// AEM suitability

HAINZL PEM-Elektrolyseur - die schlüsselfertige Lösung zur Erzeugung von grünem Wasserstoff.

// Skalierbare Plug-and-Play Lösung ab 1,25 MW Anschlussleistung

// Dynamische Betriebsweise von 10 - 100 %

// Kompaktes und Modulares Design

// Flexibilität für unterschiedliche Anwendungsfälle

// Unabhängiger Automatikbetrieb mit Fernwartung

// 24/7 Service

Optionale Features:

// Abwärmeauskopplung

// Sauerstoffnutzung

// AEM-Tauglichkeit

Components for hydrogen applications require particularly reliable and safe testing and analysis.

We develop and produce test systems with which different H2 components can be designed and tested:

// Sensors

// Valves

// Pressure-retaining equipment parts

// Fuel tanks: burst test, pressure test and leakage test in accordance with ECE_R134

Our test systems enable our partners to develop and produce safe components and systems for hydrogen applications.

Components for hydrogen applications require particularly reliable and safe testing and analysis.

We develop and produce test systems with which different H2 components can be designed and tested:

// Sensors

// Valves

// Pressure-retaining equipment parts

// Fuel tanks: burst test, pressure test and leakage test in accordance with ECE_R134

Our test systems enable our partners to develop and produce safe components and systems for hydrogen applications.

Together with partners, we develop efficient and safe hydrogen systems. We offer system solutions for compressing gaseous hydrogen to over 700 bar and for safe distribution from source to use.

Our products:

// H2 filling stations (e.g. trailers or cylinders)

// Hydrogen distribution systems (e.g. hydrogen networks)

Together with partners, we develop efficient and safe hydrogen systems. We offer system solutions for compressing gaseous hydrogen to over 700 bar and for safe distribution from source to use.

Our products:

// H2 filling stations (e.g. trailers or cylinders)

// Hydrogen distribution systems (e.g. hydrogen networks)

Our products, machines and systems are as versatile as we are. Our heart beats for mechatronics, from compact and reliable to complex and energy-efficient.