HAINZL Embedded Systems develops high-performance hardware and software for your series and accompanies you from the idea to the finished product.

We offer a complete solution comprising hardware and software, series production and after-sales service.

HAINZL Embedded Systems develops high-performance hardware and software for your series and accompanies you from the idea to the finished product.

We offer a complete solution comprising hardware and software, series production and after-sales service.

Concept development for embedded systems is the decisive step for a successful project. We offer:

// Analysis of customer requirements or the existing system

// Design of a cost-efficient and durable solution

// Consideration of security aspects such as encryption and authentication

// Support through a certified development process

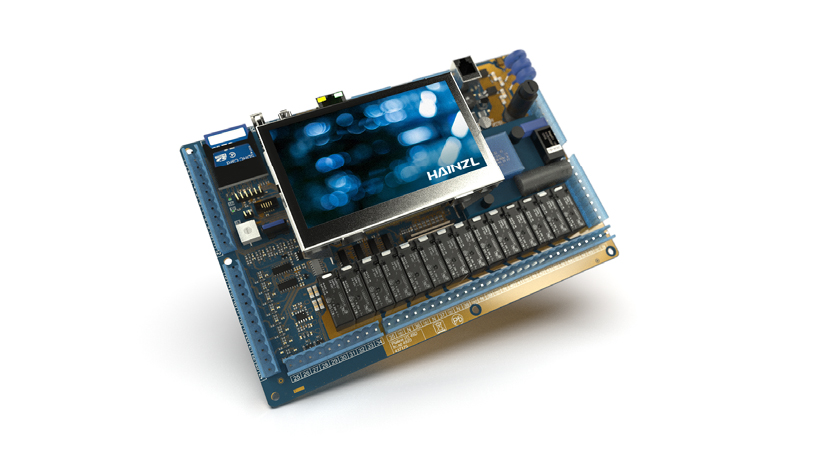

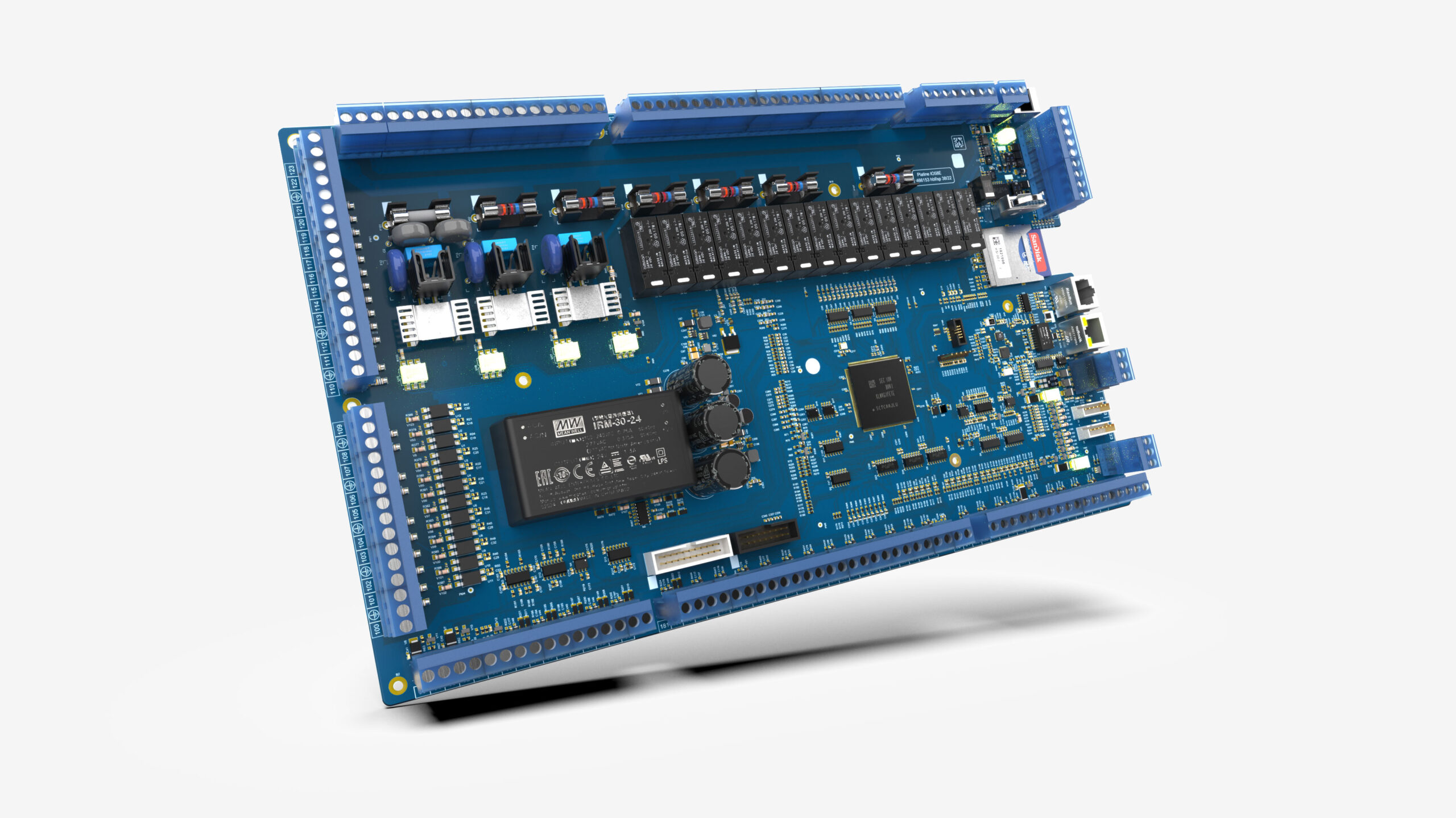

Hardware solutions for embedded systems are essential for efficient and reliable product development. We offer:

// Development of customized hardware for series applications

// Optimization of hardware for long-term availability and cost efficiency

// Utilization of experience with low-power microcontrollers up to high-performance systems

// Use of the latest development and testing technologies for EMC and safety tests

// Integration of bus systems and wireless technologies for optimum networking

Modern software solutions for embedded systems enable powerful and flexible applications. We offer:

// Modular software architecture for flexible adaptation to any requirement

// Expert knowledge for cyber security and networking in bus systems and radio technologies

// GUI development with modern frameworks such as QT, QML and Segger

// Use of open source technologies for flexible and sustainable software solutions

// Comprehensive software expertise from low-power microcontrollers to high-performance processors

// Customer-specific design for optimized operating devices and user interfaces

// Use of state-of-the-art technologies such as Linux, C++ and server-based remote maintenance solutions with data logging and parameterization

Precise and efficient production is the key to the high-quality manufacture of electronic systems. We offer:

// Use of state-of-the-art SMD assembly lines for maximum precision and reliability

// Production to the highest quality standards - “Made in Austria”, even for large quantities

// Flexible adaptation of production to individual customer requirements for an efficient supply chain

// Expandable production capacities for rapid response to short-term changes and increasing requirements

Support over the entire product life cycle ensures the sustainable functionality and further development of your systems. We offer:

// Provision of remote maintenance solutions and continuous support by experienced technicians

// Development of customized and sustainable solutions for long-term partnerships

// Design of maintenance-friendly products to maximize service life

// Efficient migration and modernization of existing technologies for future-proofing

Concept development for embedded systems is the decisive step for a successful project. We offer:

// Analysis of customer requirements or the existing system

// Design of a cost-efficient and durable solution

// Consideration of security aspects such as encryption and authentication

// Support through a certified development process

Hardware solutions for embedded systems are essential for efficient and reliable product development. We offer:

// Development of customized hardware for series applications

// Optimization of hardware for long-term availability and cost efficiency

// Utilization of experience with low-power microcontrollers up to high-performance systems

// Use of the latest development and testing technologies for EMC and safety tests

// Integration of bus systems and wireless technologies for optimum networking

Modern software solutions for embedded systems enable powerful and flexible applications. We offer:

// Modular software architecture for flexible adaptation to any requirement

// Expert knowledge for cyber security and networking in bus systems and radio technologies

// GUI development with modern frameworks such as QT, QML and Segger

// Use of open source technologies for flexible and sustainable software solutions

// Comprehensive software expertise from low-power microcontrollers to high-performance processors

// Customer-specific design for optimized operating devices and user interfaces

// Use of state-of-the-art technologies such as Linux, C++ and server-based remote maintenance solutions with data logging and parameterization

Precise and efficient production is the key to the high-quality manufacture of electronic systems. We offer:

// Use of state-of-the-art SMD assembly lines for maximum precision and reliability

// Production to the highest quality standards - “Made in Austria”, even for large quantities

// Flexible adaptation of production to individual customer requirements for an efficient supply chain

// Expandable production capacities for rapid response to short-term changes and increasing requirements

Support over the entire product life cycle ensures the sustainable functionality and further development of your systems. We offer:

// Provision of remote maintenance solutions and continuous support by experienced technicians

// Development of customized and sustainable solutions for long-term partnerships

// Design of maintenance-friendly products to maximize service life

// Efficient migration and modernization of existing technologies for future-proofing

// Partnership and expertise: With our cross-industry know-how

know-how and our experience from various industrial sectors

we offer you customized solutions that are perfectly tailored to your

perfectly tailored to your needs.

// Unlimited connectivity: Our embedded systems offer a wide

a wide range of connectivity options and enable seamless

seamless integration into your existing systems.

// Series competence: We optimize production costs,

ensure high quality and delivery reliability. Our precise production

enables the realization of large series, adapted to your specific

requirements. Benefit from decades of expertise in series production

series production for various industries.

// Made in Austria: High-quality, locally manufactured products that offer

the highest level of application expertise and reliability

worldwide.

// Your idea is the starting point: we ask the right questions

and develop the required specifications together with you.

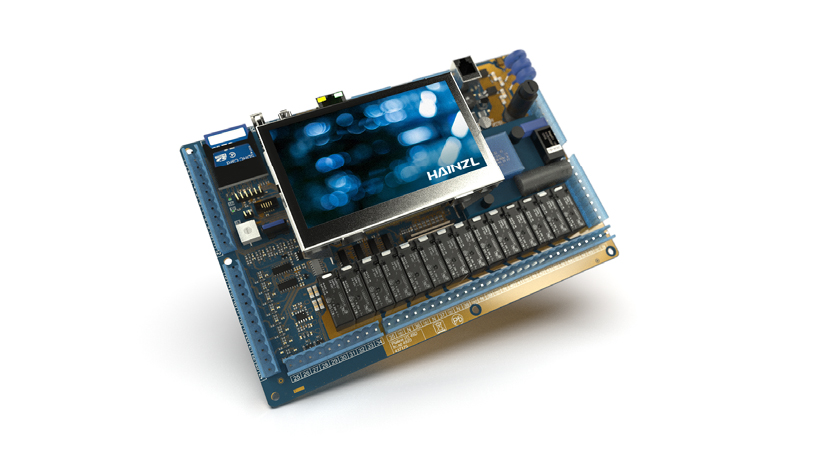

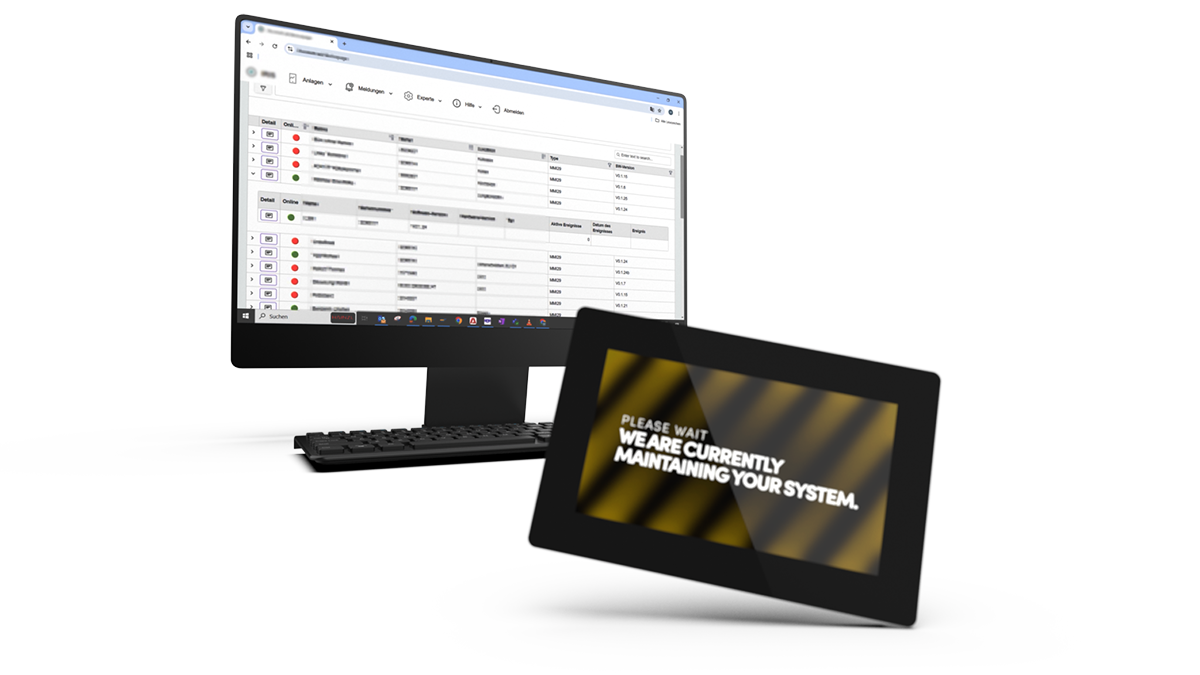

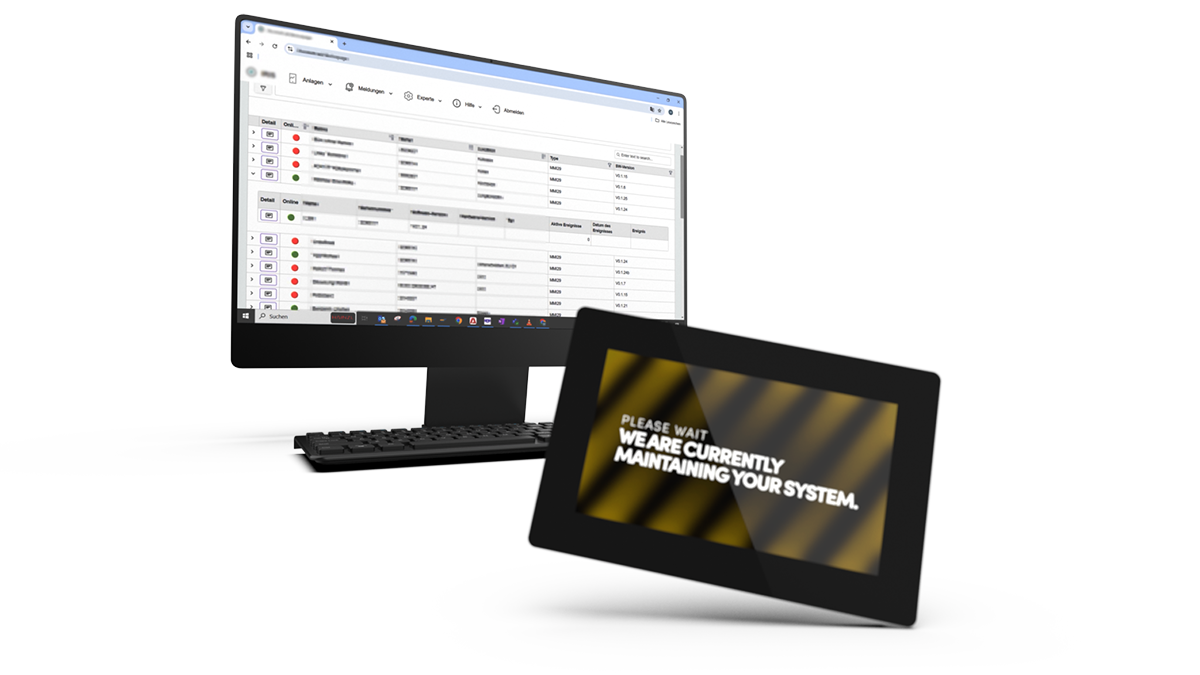

Our operating units are characterized by state-of-the-art processor technology and the Linux operating system. On the user side, our user-friendly and clearly arranged operating units impress with modern touch operation and color displays.

We develop our control systems quickly and cost-effectively from a large selection of software and hardware modules. At the customer's request, we are happy to combine the control board with an operating option.

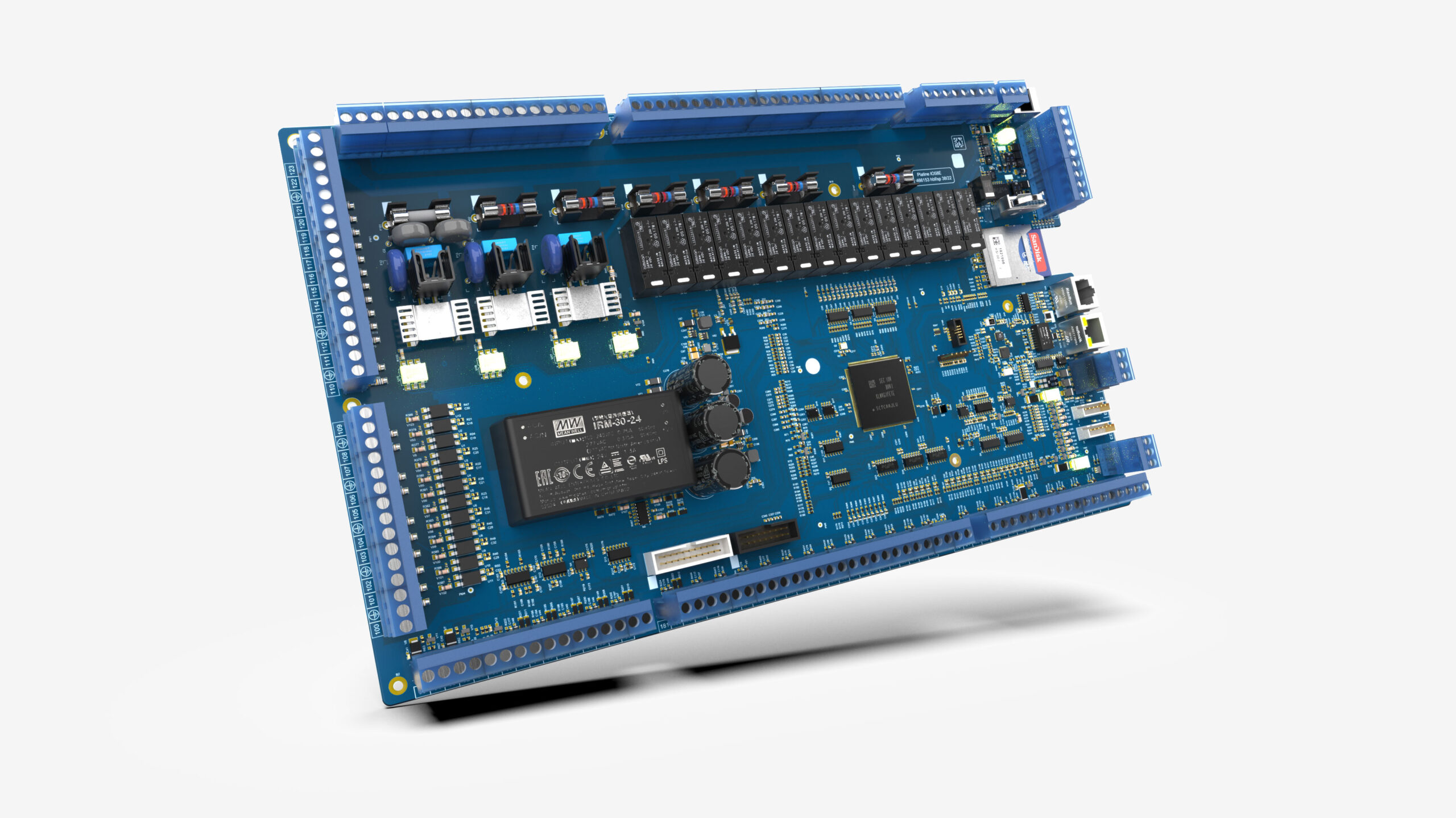

The remote maintenance package from HAINZL is a coordinated overall concept: We control embedded systems - from the device level to the server and operator level.

With our cloud-based remote solutions, you retain full control of your systems at all times - worldwide, securely and quickly.

// Remote maintenance & diagnostics

Remote error analysis and troubleshooting

// Remote control

Direct access for configuration and support

// Automatic software updates

Always up to date, experience the latest features and security updates without manual intervention

// Live monitoring & status reports

Real-time data for maximum transparency

// Multi-device compatibility

Use our solution on your PC, tablet or smartphone - anytime, anywhere.

// Secure cloud infrastructure

Encrypted connections and robust data protection for maximum security

// User-Friendly Dashboard

Intuitive operation and full control over your systems

// Flexible Deployment

Our solution works seamlessly with all major cloud providers and also supports self-hosting options.

// Maximum Efficiency

More productivity, less downtime. Optimize your workflows and increase your efficiency.

With our cloud-based remote solutions, you retain full control of your systems at all times - worldwide, securely and quickly.

// Remote maintenance & diagnostics

Remote error analysis and troubleshooting

// Remote control

Direct access for configuration and support

// Automatic software updates

Always up to date, experience the latest features and security updates without manual intervention

// Live monitoring & status reports

Real-time data for maximum transparency

// Multi-device compatibility

Use our solution on your PC, tablet or smartphone - anytime, anywhere.

// Secure cloud infrastructure

Encrypted connections and robust data protection for maximum security

// User-Friendly Dashboard

Intuitive operation and full control over your systems

// Flexible Deployment

Our solution works seamlessly with all major cloud providers and also supports self-hosting options.

// Maximum Efficiency

More productivity, less downtime. Optimize your workflows and increase your efficiency.

„Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy

eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam

voluptua.“

Max Mustermann, Hargassner Projekmanager

„Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy

eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam

voluptua.“

Max Mustermann, Hargassner Projekmanager

Electronics Manufacturing fertig seit 40 Jahren elektronische Baugruppen mit den modernsten

verfügbaren Methoden und unter Einhaltung höchster Qualitätsstandards.

Electronics Manufacturing fertig seit 40 Jahren elektronische Baugruppen mit den modernsten

verfügbaren Methoden und unter Einhaltung höchster Qualitätsstandards.