are developed and produced individually for your project.

As a leading partner for numerous industrial sectors, we offer made-to-measure hydraulic cylinders, from standard (ISO) hydraulic cylinders to highly specialized solutions in all sizes, dimensions, designs and equipment.

// Cylinder leakage detection

// Inductive end position detection

// Inductive position measuring systems

// Draw-wire stroke measuring systems

// Hydrostatic bearings

// Control blocks with piping

// Water cooling

// Special coatings

// Rotary feedthrough for media supply

// Hydraulic units

// Software, control, visualization

// Zylinder-Leckage-Erkennung

// Induktive Endlagenerkennung

// Induktive Wegmesssysteme

// Seilzugwegmesssysteme

// Hydrostatische Lagerung

// Steuerblöcke mit Verrohrung

// Wasserkühlung

// Spezialbeschichtungen

// Drehdurchführung für Medienzuführung

// Hydraulikaggregate

// Software, Steuerung, Visualisierung

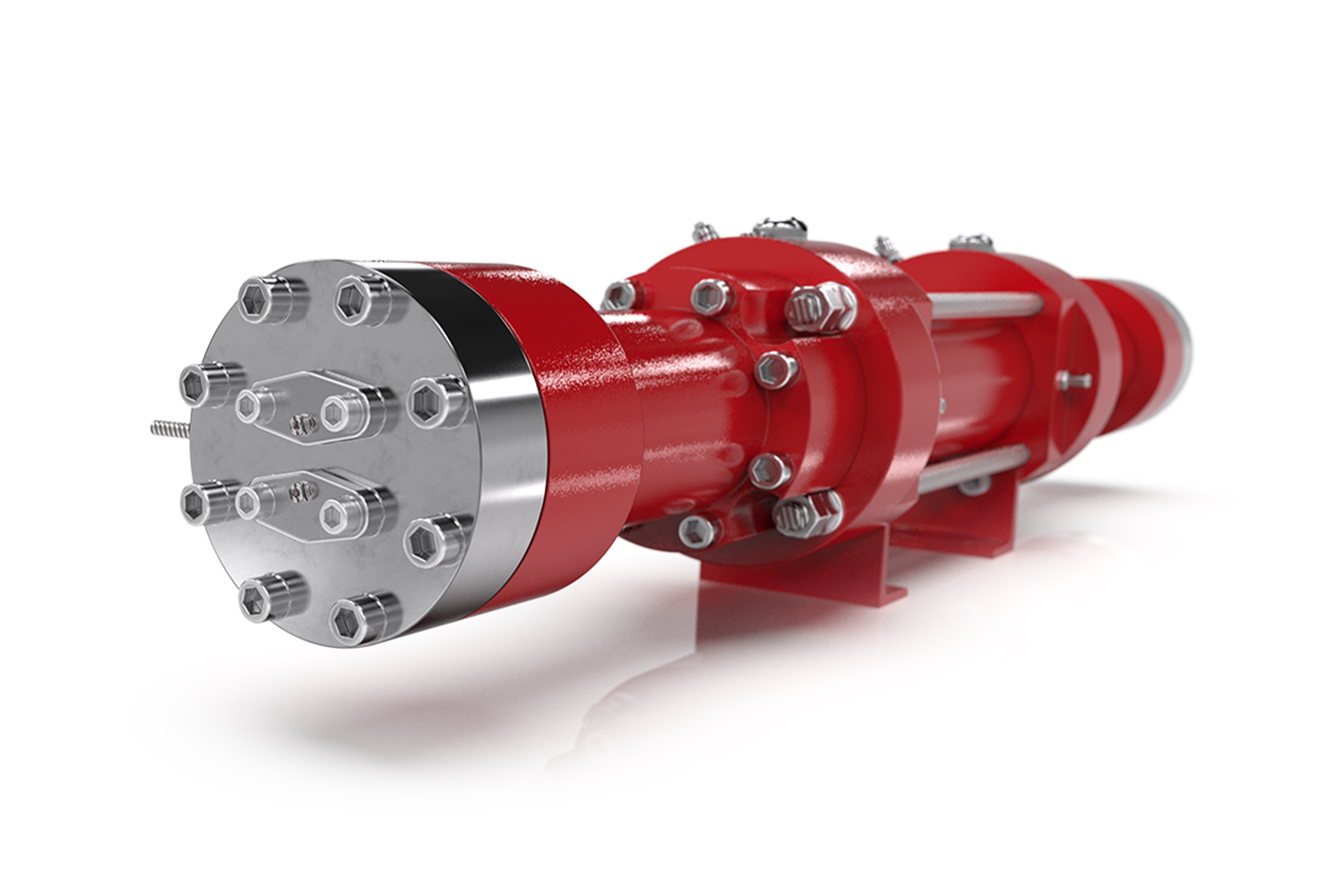

Our heavyweights and endurance runners are ideal for industry, heavy mechanical engineering and power plants. We equip your hydraulic cylinders individually with position measuring systems, water cooling, rotary feedthroughs, mechanical interlocks and many other options.

// Piston diameter: up to 1,200 mm

// Stroke lengths: up to 12,000 mm

// Nominal pressure: up to 700 bar

// Weight: up to 25 t

Depending on customer requirements, we produce our cylinders in customized versions and numerous variants with virtually no limits in terms of dimensions and design.

// Multiple cylinders

// Damping systems

// Water cooling

// Mounted rotary distributors

// Special stroke measuring systems

// Explosion-proof (ATEX)

// On/Off Shore cylinder

// Single piece or series production

Our standard cylinders are used worldwide because the mounting dimensions, installation lengths, piston rod ends and connection threads are globally standardized.

// Diameter 40 to 320 mm

// Stroke lengths up to 6 m

// Nominal pressure up to 250 bar

// Diameter 25 to 200 mm

// Stroke lengths up to 4 m

// Nominal pressure up to 10 bar

Our standard cylinders are used worldwide because the mounting dimensions, installation lengths, piston rod ends and connection threads are globally standardized.

// Diameter 40 to 320 mm

// Stroke lengths up to 6 m

// Nominal pressure up to 250 bar

// Diameter 25 to 200 mm

// Stroke lengths up to 4 m

// Nominal pressure up to 10 bar

Our hydraulic cylinders specially developed for hydraulic steel construction are individually designed and manufactured in accordance with the strict DIN 19704 standard.

The design variants include stainless steel piston rods, mechanical or hydraulic locks, special coatings and seawater-resistant versions.

Telescopic cylinders can generate large strokes with relatively short installation lengths. We also integrate individual attachments and superstructures.

// up to four stages

// single and double-acting

// Piston diameters up to 500 mm

// Stroke lengths up to 10 m

// Nominal pressure up to 500 bar

Telescopic cylinders can generate large strokes with relatively short installation lengths. We also integrate individual attachments and superstructures.

// up to four stages

// single and double-acting

// Piston diameters up to 500 mm

// Stroke lengths up to 10 m

// Nominal pressure up to 500 bar

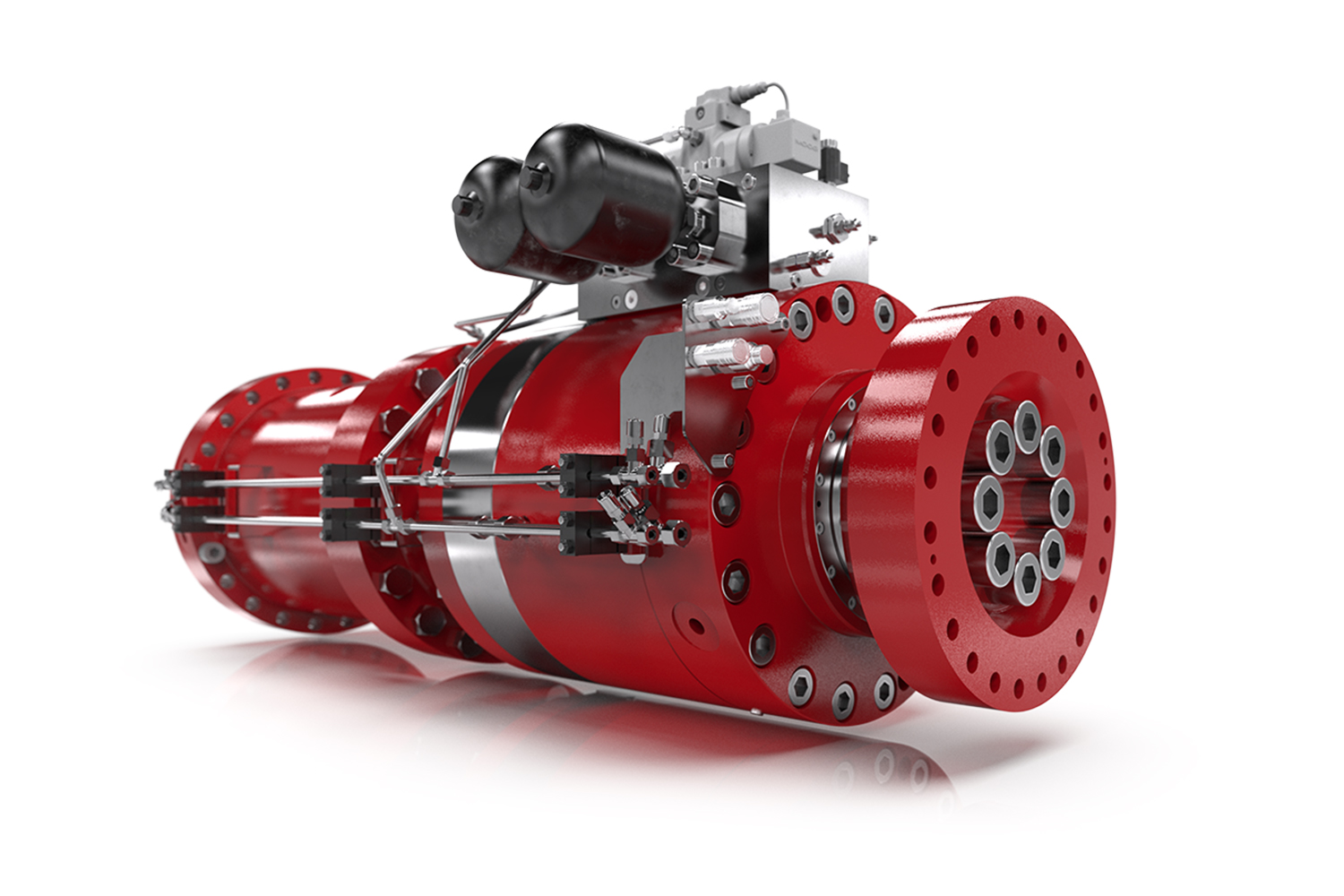

Linear hydraulic piston compressor with separating chamber system

// Compression ratio 4:1

// max. compression pressure 300 bar

// Compression medium natural gas, air, oil

// Water-cooled design

// Temperature monitoring via thermal sensor

Linear hydraulic piston compressor with separating chamber system

// Compression ratio 4:1

// max. compression pressure 300 bar

// Compression medium natural gas, air, oil

// Water-cooled design

// Temperature monitoring via thermal sensor

We extend the service life and safety of your hydraulic cylinders through comprehensive repair and maintenance. With an expert inventory and analysis, we support you with maintenance work and ensure that everything runs smoothly so that your cylinders are quickly ready for use again.

Our products, machines and systems are as versatile as we are. Our heart beats for mechatronics, from compact and reliable to complex and energy-efficient.