for the transmission of media such as oil, air, grease, gas, water, emulsion, or vacuum between stationary and rotating machine parts, and they are used in almost all industries.

Our strength lies in the design of special versions and tailored solutions. We deliver durable and robust rotary joints that withstand high temperatures, pressures, and rotational speeds.

We adapt perfectly to your design—whether it's a single product or serial production. This ensures smooth and long-term operation of your machines.

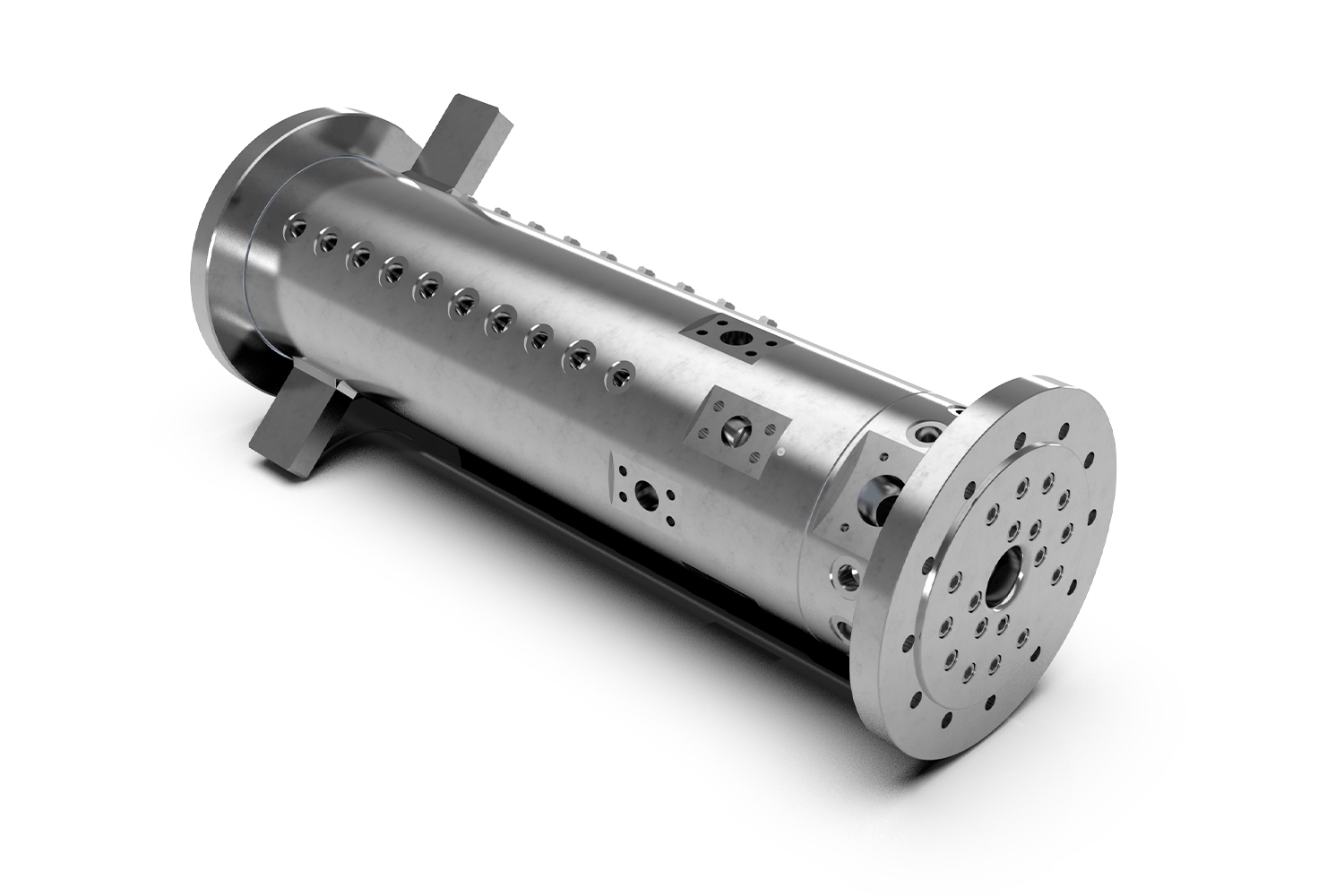

This rotary union is used for slow rotary and swivel movements. Sealed separation channels allow different media to be transferred simultaneously and without leakage.

// 100 rpm

// 120°C

// e.g. rotary table of injection molding machines

This rotary union is used for slow rotary and swivel movements. Sealed separation channels allow different media to be transferred simultaneously and without leakage.

// 100 rpm

// 120°C

// e.g. rotary table of injection molding machines

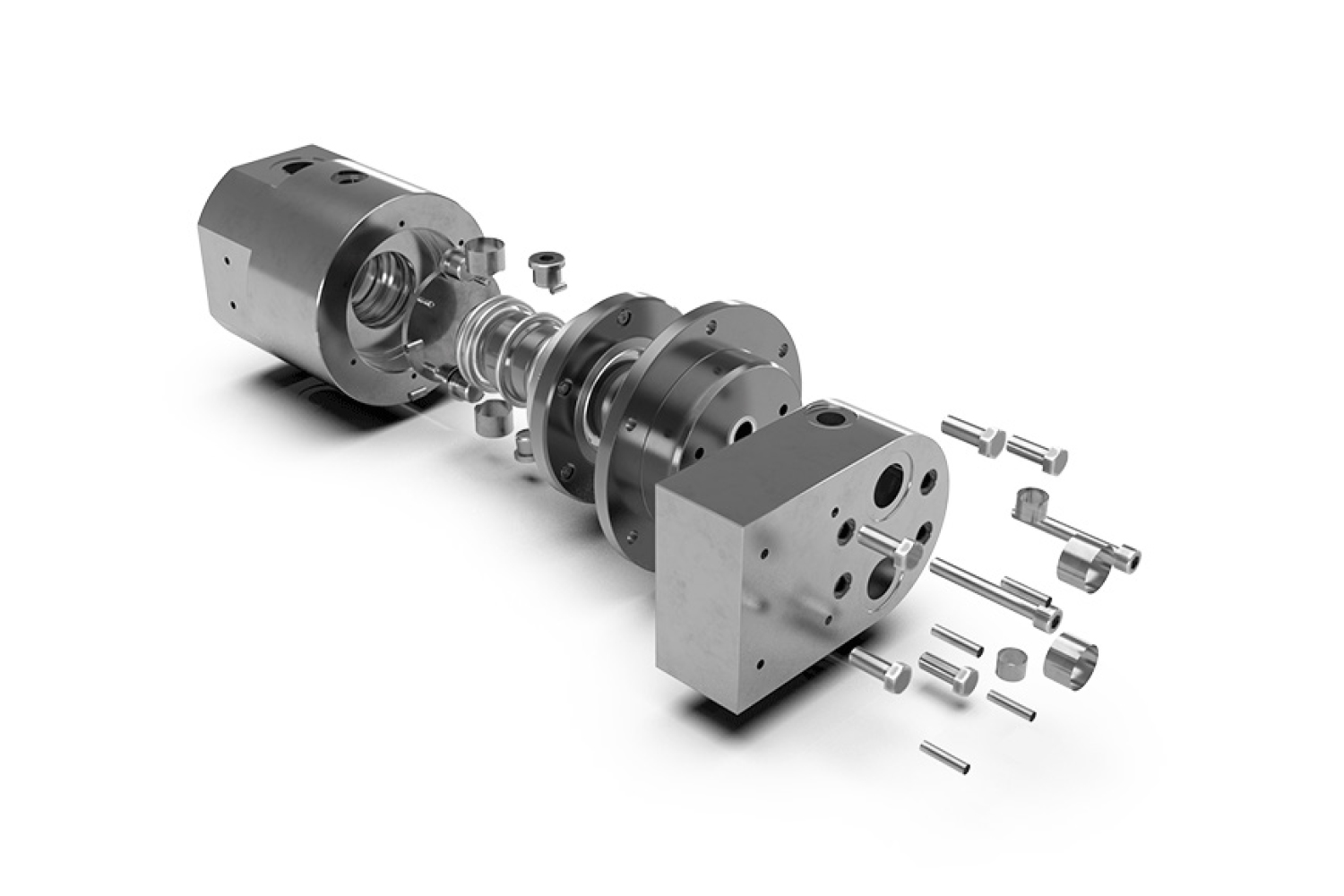

This special version is particularly robust. The wear-resistant coating with a hardness of up to 2,300 HV and the sealing system, which has been tried and tested in long-term tests, increase the service life and extend maintenance intervals.

// 100 rpm

// 120°C

// e.g. ladle turret in steelworks

This special version is particularly robust. The wear-resistant coating with a hardness of up to 2,300 HV and the sealing system, which has been tried and tested in long-term tests, increase the service life and extend maintenance intervals.

// 100 rpm

// 120°C

// e.g. ladle turret in steelworks

This design is based on materials that can withstand high temperatures in the long term. This means that media can be transferred to the rotating parts in a hot state (up to 140°C).

// 100 rpm

// 140°C

// e.g. mold changing units

This design is based on materials that can withstand high temperatures in the long term. This means that media can be transferred to the rotating parts in a hot state (up to 140°C).

// 100 rpm

// 140°C

// e.g. mold changing units

Gap seals are used where high speeds are required. The non-contact sealing system ensures low friction losses even at high speeds.

// 1,000 rpm

// 120°C

// e.g. reel applications

Gap seals are used where high speeds are required. The non-contact sealing system ensures low friction losses even at high speeds.

// 1,000 rpm

// 120°C

// e.g. reel applications

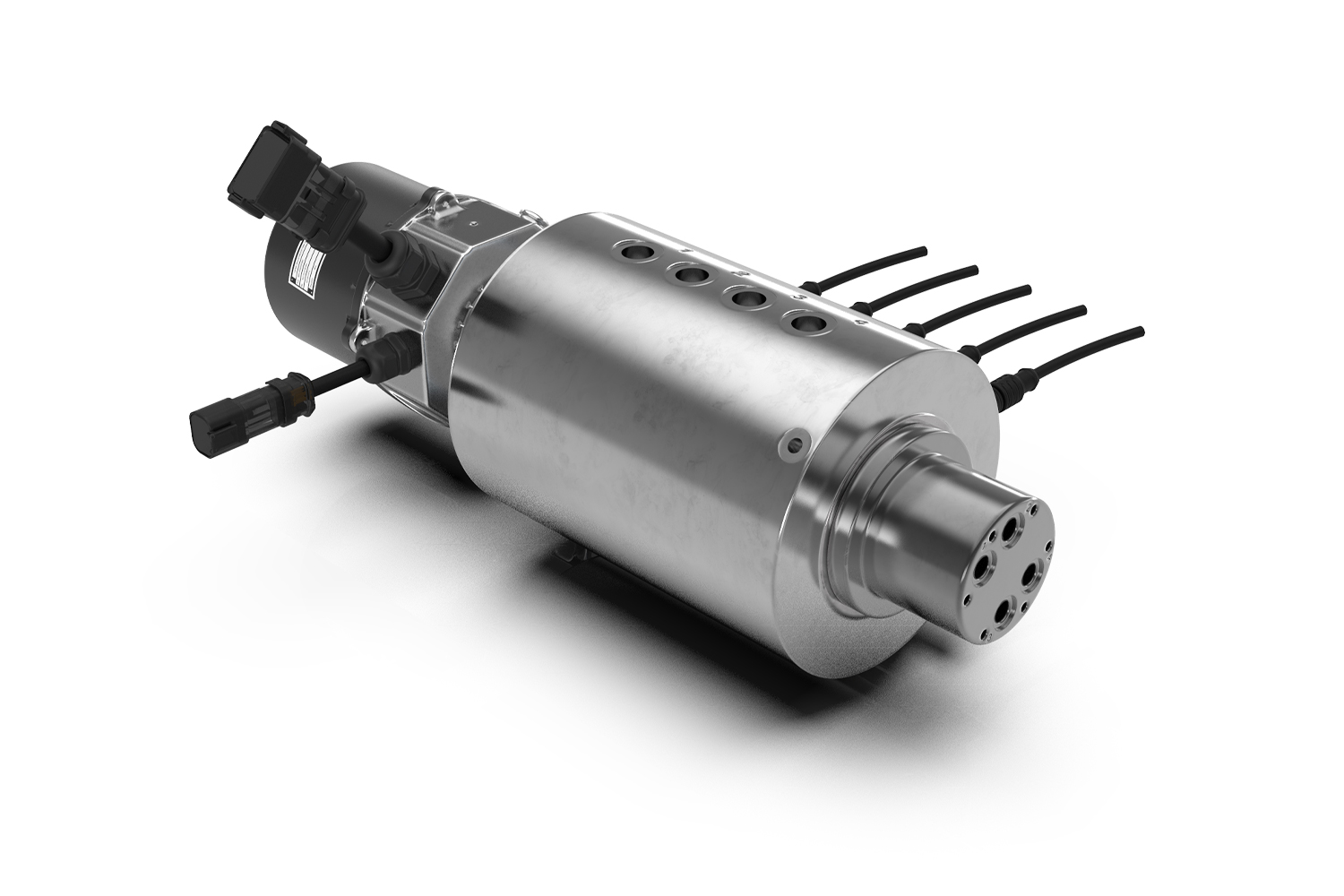

Rotary feedthroughs can be combined with electrical slip rings or cylinders and integrated into an application. Slip ring designs transmit a wide variety of media (oil, air, grease, gas, water, emulsion or vacuum) as well as power, signals and data.

// e.g. turbine vane adjustment cylinders

// e.g. mold changing units

Rotary feedthroughs can be combined with electrical slip rings or cylinders and integrated into an application. Slip ring designs transmit a wide variety of media (oil, air, grease, gas, water, emulsion or vacuum) as well as power, signals and data.

// e.g. turbine vane adjustment cylinders

// e.g. mold changing units

We will be happy to advise you to find the right design for your individual application.

Our service includes:

// Advice and implementation

// New design, adaptation or repair

// Also for existing systems with third-party products

We will be happy to advise you to find the right design for your individual application.

Our service includes:

// Advice and implementation

// New design, adaptation or repair

// Also for existing systems with third-party products

Our products, machines and systems are as versatile as we are. Our heart beats for mechatronics, from compact and reliable to complex and energy-efficient.